Ukuthelekiswa kweenkqubo zezinto zesekethe ezidityanisiweyo ze-photonic

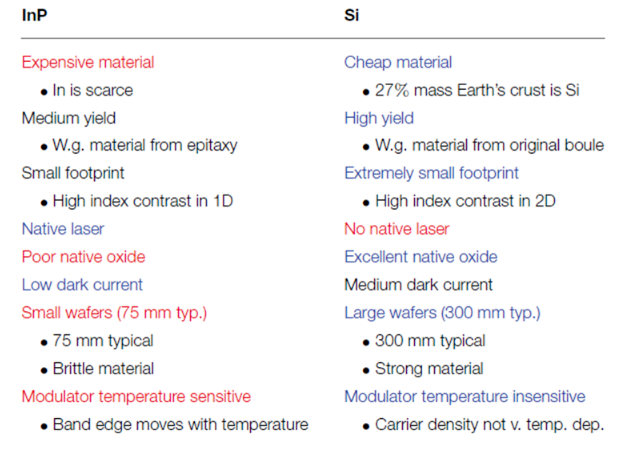

Umfanekiso 1 ubonisa uthelekiso lweenkqubo ezimbini zezinto, i-indium Phosphorus (InP) kunye ne-silicon (Si). Ukunqaba kwe-indium kwenza i-InP ibe yinto ebiza kakhulu kune-Si. Ngenxa yokuba iisekethe ezisekelwe kwi-silicon zibandakanya ukukhula okuncinci kwe-epitaxial, isivuno seesekethe ezisekelwe kwi-silicon sihlala siphezulu kuneseesekethe ze-InP. Kwiisekethe ezisekelwe kwi-silicon, i-germanium (Ge), edla ngokusetyenziswa kuphela kwiIsixhobo sokubona iifoto(izixhobo zokubona ukukhanya), ifuna ukukhula kwe-epitaxial, ngelixa kwiinkqubo ze-InP, nee-waveguides ezingasebenziyo kufuneka zilungiswe ngokukhula kwe-epitaxial. Ukukhula kwe-Epitaxial kudla ngokuba noxinzelelo oluphezulu lwesiphene kunokukhula kwekristale enye, njengokuvela kwi-crystal ingot. Ii-waveguides ze-InP zinomahluko ophezulu we-refractive index kuphela kwi-transverse, ngelixa ii-waveguides ezisekelwe kwi-silicon zinomahluko ophezulu we-refractive index kwi-transverse nakwi-longitudinal, okuvumela izixhobo ezisekelwe kwi-silicon ukuba zifezekise i-radii encinci yokugoba kunye nezinye izakhiwo ezincinci. I-InGaAsP ine-band gap ethe ngqo, ngelixa i-Si kunye ne-Ge zingenawo. Ngenxa yoko, iinkqubo zezinto ze-InP zingcono ngokubhekiselele ekusebenzeni kakuhle kwe-laser. Ii-oxides ezingaphakathi zeenkqubo ze-InP azizinzanga kwaye ziqinile njenge-intrinsic oxides ze-Si, i-silicon dioxide (SiO2). I-Silicon yinto enamandla kune-InP, evumela ukusetyenziswa kobukhulu obukhulu be-wafer, oko kukuthi ukusuka kwi-300 mm (kungekudala iza kuphuculwa ukuya kwi-450 mm) xa kuthelekiswa ne-75 mm kwi-InP. I-InPiimodulatorskudla ngokuxhomekeka kwisiphumo seStark esinqunyelwe yi-quantum, esinobuthathaka kubushushu ngenxa yentshukumo yomphetho webhendi ebangelwa bubushushu. Ngokwahlukileyo koko, ukuxhomekeka kubushushu kwiimodulators ezisekelwe kwi-silicon kuncinci kakhulu.

Itekhnoloji ye-silicon photonics ithathwa njengefanelekileyo kuphela kwiimveliso ezingabizi kakhulu, ezimfutshane, nezinomthamo ophezulu (ngaphezulu kweziqwenga ezi-1 yezigidi ngonyaka). Oku kungenxa yokuba kuyamkelwa ngokubanzi ukuba kufuneka umthamo omkhulu we-wafer ukuze kusasazwe iindleko zemaski kunye nophuhliso, kwaye okoitekhnoloji ye-silicon photonicsineengxaki ezinkulu zokusebenza kwizicelo zemveliso ezisuka kwisixeko ukuya kwisixeko ukuya kwesinye kunye nezicelo zemveliso ezithatha ixesha elide. Nangona kunjalo, enyanisweni, okuchaseneyo kuyinyani. Kwizicelo ezingabizi kakhulu, ezimfutshane, ezivelisa imveliso ephezulu, i-vertical cavity surface-emitting laser (VCSEL) kunyei-laser eguquliweyo ngokuthe ngqo (Ileyiza ye-DML): i-laser eguquliweyo ngokuthe ngqo ibangela uxinzelelo olukhulu lokhuphiswano, kwaye ubuthathaka betekhnoloji ye-photonic esekwe kwi-silicon engenakukwazi ukudibanisa ii-laser ngokulula bube yingxaki enkulu. Ngokwahlukileyo koko, kwi-metro, usetyenziso olude, ngenxa yokukhetha ukudibanisa itekhnoloji ye-silicon photonics kunye ne-digital signal processing (DSP) kunye (ehlala ikwiindawo ezinobushushu obuphezulu), kuluncedo ngakumbi ukwahlula i-laser. Ukongeza, itekhnoloji yokufumanisa ehambelanayo inokwenza iintsilelo zobuchwepheshe be-silicon photonics kakhulu, njengengxaki yokuba umbane omnyama mncinci kakhulu kune-local oscillator photocurrent. Kwangaxeshanye, akulunganga ukucinga ukuba kufuneka umthamo omkhulu we-wafer ukugubungela iindleko zemaski kunye nophuhliso, kuba itekhnoloji ye-silicon photonics isebenzisa ubungakanani bee-node ezinkulu kakhulu kune-complementary metal oxide semiconductors (CMOS) eziphambili, ngoko ke iimaski ezifunekayo kunye nokusebenza kwemveliso zixabiso eliphantsi.

Ixesha lokuthumela: Agasti-02-2024